Quality Control and Product Consistency: The Cornerstone of Successful Eyewear Frame Manufacturing

Introduction: Why Quality Control Matters in the Eyewear Frame Industry

In the competitive global eyewear market, maintaining consistent quality is not just a manufacturing goal—it’s a business imperative. For international buyers sourcing eyewear frames from China’s manufacturing hubs like Wenzhou, quality control represents the difference between building a trusted brand and facing costly returns, customer dissatisfaction, and reputation damage. This article explores the critical aspects of quality control and product consistency in eyewear frame manufacturing, providing insights for optical professionals seeking reliable production partners.

The Multi-Stage Quality Control Process

Effective quality control in eyewear frame manufacturing isn’t a single checkpoint—it’s a comprehensive process integrated throughout the production cycle. Leading manufacturers implement systematic quality assurance at multiple stages:

1. Raw Material Inspection

Quality begins with materials. Premium manufacturers conduct rigorous testing of all incoming materials, including acetate sheets, metal alloys, and finishing components. This includes checks for material purity, color consistency, structural integrity, and compliance with safety standards.

2. In-Process Quality Control

During production, each critical manufacturing stage requires monitoring and verification. This includes checking frame dimensions, ensuring precise cutting, verifying hinge functionality, and assessing initial assembly quality.

3. Final Product Inspection

Comprehensive inspection of finished frames includes functional testing, aesthetic evaluation, comfort assessment, and durability checks. Advanced manufacturers implement AQL (Acceptable Quality Level) standards to ensure statistical reliability of their inspection processes.

Certification and Compliance

Professional eyewear frame manufacturers adhere to international standards and certifications to ensure consistent quality. Our factory proudly holds the following certifications:

CE Certification

This European standard confirms that our products meet EU safety, health, and environmental protection requirements. It’s a crucial indicator of quality for European market entry.

12870 Standard

This certification ensures our frames meet specific technical standards for mechanical resistance, stability, and dimensional accuracy—key factors in creating durable, comfortable eyewear frames.

UV Protection for Sunglasses

While we specialize in frames rather than lens manufacturing, we ensure our sunglasses frames are designed to properly accommodate UV-protective lenses, with appropriate certification for the complete product.

Ensuring Batch-to-Batch Consistency

One of the biggest challenges in eyewear frame manufacturing is maintaining consistency across different production runs. Professional manufacturers implement several strategies to achieve this:

Color Matching Systems

Digital color management systems and standardized color references ensure consistent coloration across different production batches, even when materials are sourced at different times.

Master Samples

Production is guided by approved master samples that serve as the definitive reference point for all quality parameters. These samples are stored in controlled environments to prevent degradation.

Statistical Process Control

Advanced manufacturers implement SPC methodologies to monitor production variables, identify trends, and make proactive adjustments before quality issues emerge.

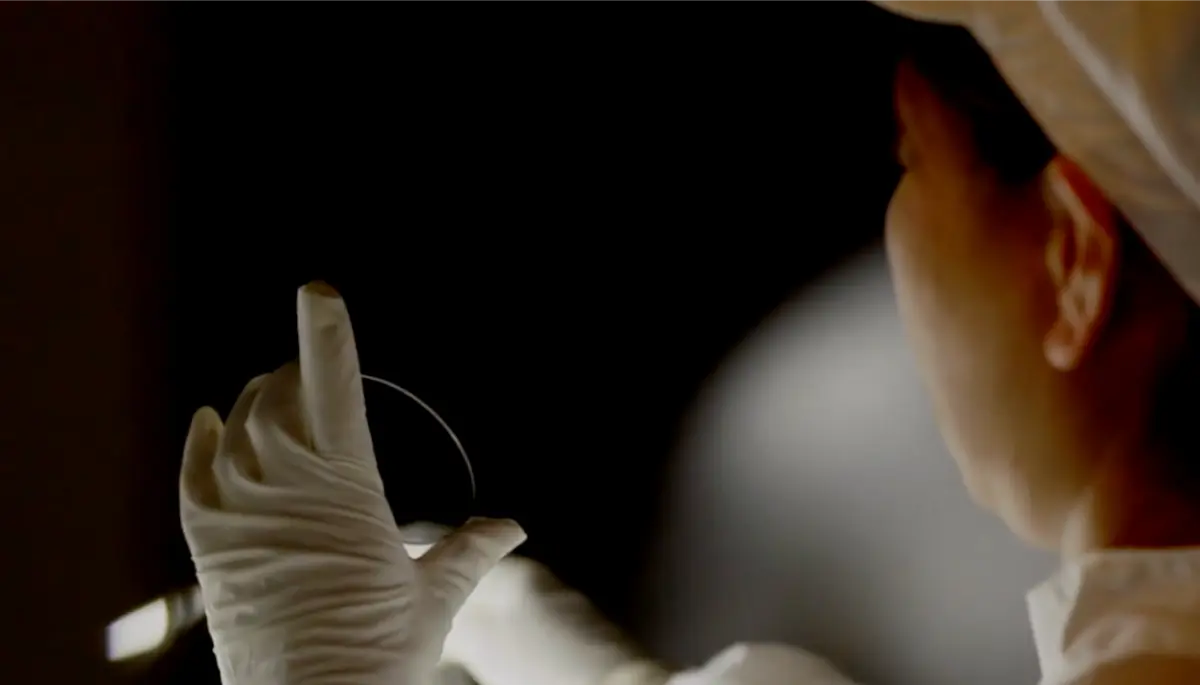

Frame-Specific Quality Control Measures

As a specialized eyewear frame manufacturer, we implement specific quality control measures focused on frame excellence:

Structural Integrity Testing

Frames undergo stress testing to ensure they maintain their shape under normal usage conditions. This includes temple flexibility tests, frame twist resistance, and pressure point analysis.

Finishing Quality

Every frame undergoes meticulous inspection for surface quality, including checks for scratches, color consistency, polishing quality, and coating durability.

Hardware Functionality

Critical components like hinges, nose pads, and temple tips receive special attention, with multiple operation tests to ensure smooth functionality and long-term durability.

Documentation and Traceability

Quality manufacturers maintain comprehensive documentation systems that enable complete traceability of products:

Production Records

Detailed records of production parameters, material sources, and quality check results allow manufacturers to identify the source of any issues that arise.

Batch Coding

Professional eyewear producers implement batch coding systems that allow any product to be traced back to specific production runs, materials, and even individual machine operators.

Digital Quality Management Systems

Advanced manufacturers use integrated QMS software to track quality metrics, generate analytical reports, and drive continuous improvement initiatives.

Partner Selection: Evaluating a Frame Manufacturer’s Quality Control Systems

For international buyers, assessing a potential manufacturing partner’s quality control capabilities is essential. Consider these factors when evaluating eyewear frame manufacturers:

Certification Verification

Confirm that the manufacturer holds relevant certifications like CE and 12870, demonstrating commitment to standardized quality management processes.

Material Expertise

Evaluate the manufacturer’s knowledge of frame materials—from traditional acetates to advanced composites—and their ability to maintain quality across different material types.

Transparency

Quality-focused manufacturers welcome client visits and openly share their quality control procedures, test results, and continuous improvement initiatives.

Track Record

Request references from existing clients and inquire specifically about consistency across multiple orders and the manufacturer’s response to quality-related issues.

Conclusion: Quality as a Competitive Advantage

In today’s global eyewear market, consistent quality isn’t just about avoiding problems—it’s a powerful competitive advantage. By partnering with dedicated frame manufacturers who prioritize rigorous quality control processes, international optical professionals can build stronger brands, reduce operational headaches, and ultimately deliver superior value to their customers. As you prepare for industry events like the Wenzhou International Optical Fair, make quality control capabilities a key criterion in your manufacturer selection process.